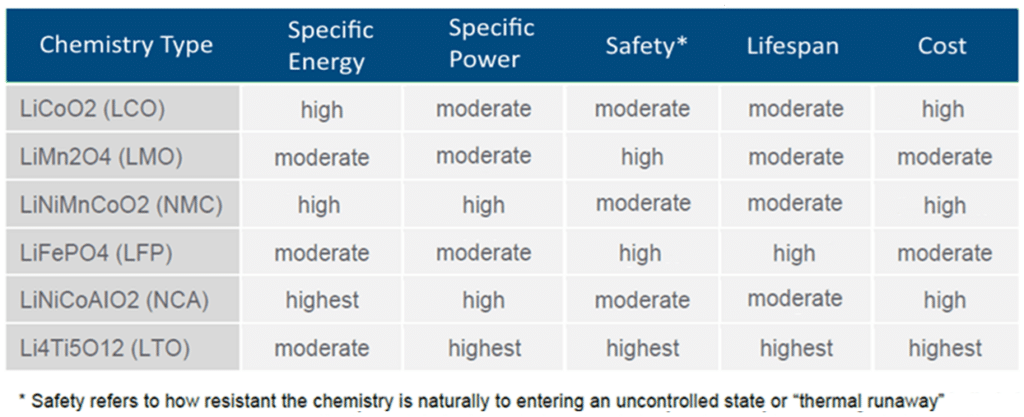

Lithium batteries power everything from consumer electronics to electric cars and forklifts to backup power systems, and the chemistry plays a role in performance, lifespan, cost and safety.

Lithium batteries are an important chemistry where high energy density is needed to power everything from consumer electronics to electric cars and forklifts to backup power systems. While they all share lithium as a common element, the specific chemical composition of the different lithium batteries significantly impacts performance, lifespan, cost and safety.

To better understand how different lithium battery chemistries serve various industries, let’s explore some of the most common types:

Lithium Cobalt Oxide (LiCoO2 or LCO)

LCO batteries are commonly used in consumer electronics such as smartphones, laptops, tablets, etc. Known for their high energy density, they offer long runtimes in compact forms. Combined with moderate power and lifespan make this chemistry ideal for these lightweight consumer applications.

Lithium Manganese Oxide (LiMn2O4 or LMO)

While LMO batteries have a moderate energy density and specific power, their higher safety aspects made them the preferred chemistry for the first-generation Nissan Leaf electric vehicles. LMO batteries can also be found in power tools and medical devices.

Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2 or NMC)

The NMC batteries deliver high energy density and high specific power, making this chemistry the popular choice for electric vehicles and energy storage systems. Because of its balance of power and endurance, NMC is well-suited for heavy-duty lift truck fleets in 24×7 operations with limited charging opportunities.

Lithium Iron Phosphate (LiFePO4 or LFP)

Known for its safety, longer cycle life and ability to charge and discharge quickly, LFP is becoming a favorable option because the material content is more abundant and easier to source, so the supply chain is less vulnerable to disruption. While LFP batteries have a lower energy density compared to NMC or LCO, its lower cost, durability and safety make it an ideal choice for the material handling industry, where reliability and longevity are paramount.

Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2 or NCA)

NCA batteries offer the highest energy density and high power, like NMC, but with a similar lifespan. NCA batteries are mostly used in premium electric vehicles.

Lithium Titanate (LiTi5O12 or LTO)

Finally, LTO batteries are known for their exceptional lifespan, fast charging capabilities and low risk of thermal runaway. However, their energy density is lower than most other lithium chemistries. LTO’s biggest drawback is its high cost, because of the lithium content in the cathode and anode. LTO is mainly used in limited commercial applications.

Stryten Energy’s M-Series Lithium Solutions

Stryten Energy’s M-Series Li600 is based on the LFP chemistry, offering greater efficiency, faster charging and increased cycle life, all in a maintenance-free package. Available for Class I, Class II and Class III motive power applications, the Li600 provides all the power you need to get the job done.