Mike Berger, Director of Product Engineering at Stryten Energy, discusses the contributions that safe, proven and reliable lead batteries can make in the transition to clean energy.

Mike Berger, Director of Product Engineering for Stryten Energy, was recently featured on the Beyond Lithium podcast, hosted by Nate Kirchhofer, CEO and Co-founder of BioZen Batteries. Berger shares his thoughts on the contributions that safe, proven and reliable lead batteries can make in the transition to clean energy.

Berger plays a major role in designing Stryten Energy’s lead batteries to ensure their performance, quality and cost meet customer requirements across a wide range of applications. Berger says, “Someone once described lead batteries… ‘it’s not rocket science.’ Actually, they’re a little bit more complicated than rocket science because it takes chemistry, electricity, and materials… all those things put together in order to develop a battery.”

There are tradeoffs between cost and performance that must be made on the design side to make a battery that meets the customer’s requirements at a good value to them.

U.S. Manufacturing and the Circular Economy

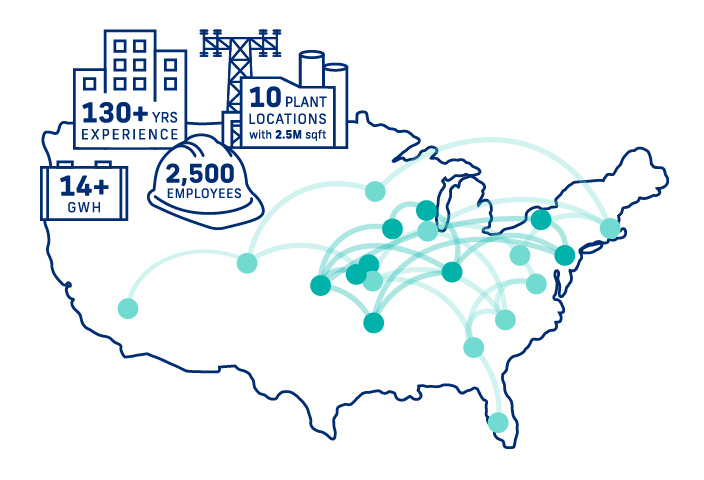

Berger mentions that although there is a market for imports, lead batteries have a strong domestic manufacturing industry. The lead battery industry supplies 90 percent of domestic demand with batteries designed and manufactured in the U.S.

Stryten Energy’s manufacturing capacity meets the needs of numerous industry sectors. Stryten produces approximately 14 gigawatt hours annually in energy storage, across 10 plant locations covering over 2.5 million square feet of manufacturing space. This positions the company as the third largest energy storage manufacturer in the U.S.

We operate in four major market segments: essential power, motive power, transportation, and military and government,” explains Berger. “Our stored energy technologies include advanced lead, lithium and vanadium redox flow batteries, as well as intelligent chargers and energy performance management software.”

Kirchhofer turns the conversation to the circular economy and recyclability of lead batteries. Berger references a study that notes over 99 percent of lead batteries are recycled in the U.S. In fact, 100 percent of the lead Stryten Energy uses in its products is recycled lead.

There are systems in place to collect lead batteries at the end of life, recycle them and produce more lead batteries. Kirchhofer notes, “This circular economy, this infrastructure and economy that’s built around lead is laudable and other technologies should really be aiming for something similar.”

As for lithium, less than 5 percent of lithium batteries are recycled. As energy storage requirements increase, Berger asks, “Do we have enough lithium to meet the needs of the increased energy storage requirements? If not, how do we recycle the lithium?”

There is a significant amount of capital and research being invested to find a solution to recover the precious metals in lithium batteries. The lead battery industry has provided a path to create a successful circular economy.

Addressing Energy Storage Challenges

According to Berger, the amount of energy storage needed is projected to triple within the next 10 years. Ensuring the U.S. has enough resources to keep up with energy storage demands is one of the main challenges.

Because lead batteries have a proven history of over 100 years, their limitations are well known. However, he notes that there is still much opportunity for research and development to improve their material utilization and cycle life so they can operate in even more applications. With the new opportunities in energy storage, coupled with efforts to improve performance, there will be a place for lead batteries.

For example, EV fast charge buffer systems are a good opportunity for lead batteries. On some routes, there may not be enough power running to those charging stations. Battery storage would be a way to ensure vehicles can be charged quickly at a cost of power that is affordable.

In Berger’s opinion, another challenge is understanding which battery technology is best suited for what applications as energy storage needs increase. The energy density of lead is less than lithium, so when there is an application that needs as much energy as possible in a small space, lead is not the answer.

In areas where weight and/or space are not constrained, lead can do the job if you select the right size battery and operate it accordingly. Berger believes all chemistries will serve a purpose in the future of energy storage.

What Sets Stryten Energy Apart

With a portfolio of advanced lead, lithium, and vanadium redox flow batteries, Stryten Energy is well-positioned to be technology agnostic. “We believe that our manufacturing expertise can be translated to the other chemistries and that we can share best practices in those regards,” says Berger, “The fact that we can offer three chemistries means that we can offer our customers what’s right for them.”

Berger closes the conversations by saying, “Lead chemistry is available, affordable, recyclable, safe, reliable and well understood. We should not dismiss lead technology just because of its age. There is a great opportunity to optimize lead for these new challenges that are before us.”

Listen to the full podcast on Beyond Lithium.