First In First Out Maximizes Battery Life

How are lead batteries like milk? They can both go bad. Milk eventually sours, and batteries gradually lose their charge. For automotive retailers, batteries need to be considered “perishable goods” and should be inventoried and merchandised similarly.

The most effective approach for perishable items is the FIFO method. FIFO stands for First In/First Out. This inventory method is actually as simple as it sounds: items that arrive first at the warehouse or store are shipped and sold first.

Rotating Stock

If racks are loaded from the front, those older batteries keep getting pushed back. Eventually, they may move to the front, but it could be months later. By that time, the battery has been sitting on the shelf too long and might be in need of charging. Sulfation could also occur, affecting battery life and performance.

Instead, when a new shipment arrives, racks should be loaded from the back. This method shifts the older inventory to the front, to be purchased by the next consumer. Most retailers have a six-month rotation program in place. When new batteries arrive, a rotation credit may be issued for those that are older.

Reading Date Codes

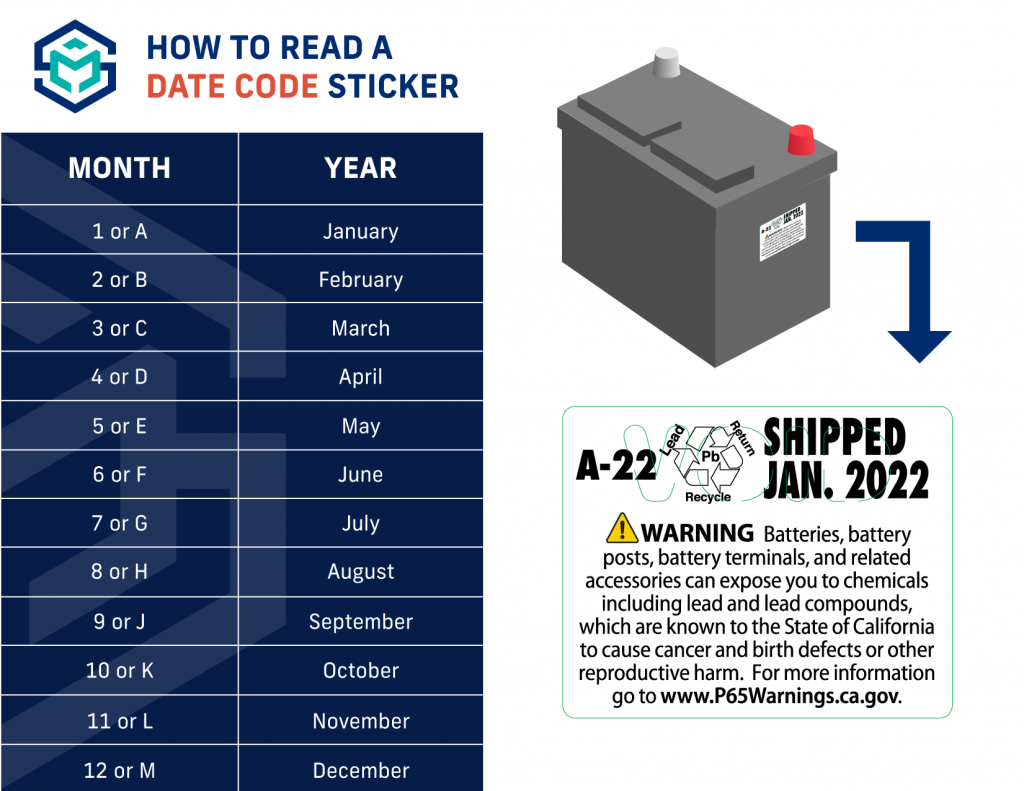

Similar to milk and other perishable goods, automotive batteries are dated to help with inventory rotation. Many battery manufacturers and installers use a date code system to help establish warranty dates.

The date code is typically a combination of letters and numbers that indicate the month and year the battery was manufactured. The ship date indicates when the battery left the plant. Any date code sticker that is removed will leave the word VOID on the battery, meaning the warranty is no longer valid.

Ensuring the Right Stock

Knowing the right products to stock at the right time is key to maximizing sales. Stryten offers Category Management Services that leverage multiple data sources from trusted industry-leading resources, along with internal data and expertise, to provide actionable insights for growing the category and maximizing profits.

With market-based product assortments, you can make sure the right batteries are in stock at the right time and place. This approach helps to make sure that optimum inventory levels and velocities are maintained to minimize the risk of aged products sitting on the shelf.

By utilizing the FIFO rotation method and engaging with category management services, you will help mitigate warranty and rotation problems, as well as alleviate potential customer satisfaction issues.