In the last year or two, there have been a number of new names and acronyms that have been introduced into the automotive battery lexicon: Enhanced Flooded Battery (EFB), Advance Flooded Battery (AFB) and Robust Batteries. How are they unique, and what do they offer the consumer? Which one actually offers different technology, and which are just adjectives?

Battery Council International (BCI) recognizes three basic automotive battery technologies: Flooded Battery, EFB Battery and Absorbent Glass Mat (AGM) Battery. The AGM battery is unique from the first two as the electrolyte is immobilized in a non-spillable configuration. In both the Flooded and EFB types, the electrolyte is free flowing.

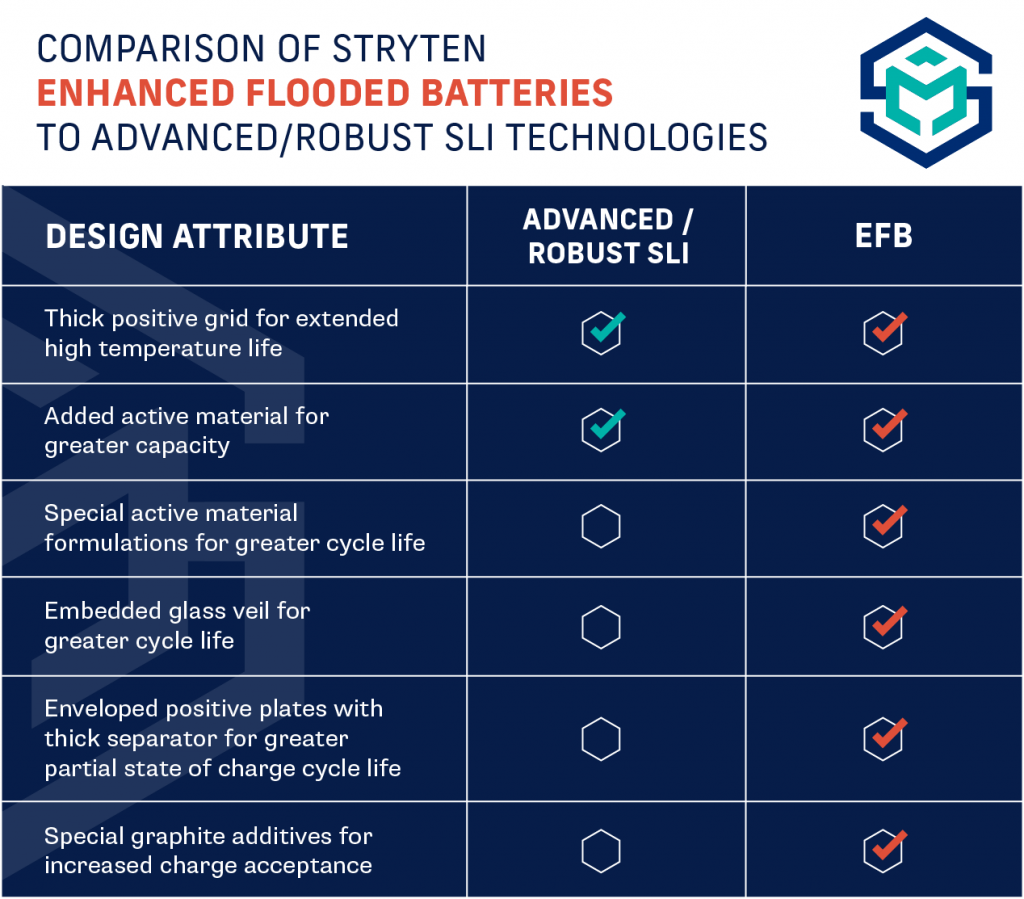

By the BCI definition, an EFB is “a flooded lead acid battery with enhanced cycling capability and charge recovery compared to standard flooded starter batteries.” Taking this a step further, EFB batteries are designed to different standards and manufactured with different attributes and techniques to fully differentiate themselves from the standard Flooded Battery group. This includes the ones that use adjectives like “Advanced” and “Robust” that imply something unique, but are just incremental versions of the standard Flooded Battery.

Advanced and Robust batteries are generally staged as the “Best” of a Good/ Better/Best battery line up. Their identifying features are generally that they are of higher capacity and/or have thicker positive grids then the standard products. These Advanced/Robust batteries are designed towards excelling under the standard Starting, Lighting and Ignition (SLI) requirements, which are governed under industry standards SAE J537, J2801 and /or EN50342-1.

EFB batteries, on the other hand, are designed to meet the standards for SLI batteries, plus the additional requirements for vehicles with the capability to automatically switch off the engine during vehicle operation either in standstill or moving (“Start-Stop”), as well as the capability to recover braking energy or energy from other sources. EFB batteries are designed to meet the requirements of a higher set of standards governed by SAE J3012 and/or EN50342-6. These two standards include demanding partial state of charge cycling and dynamic charge acceptance requirements that the SLI requirements do not.

So EFB batteries are held to higher performance standards than Advanced or Robust batteries. Do these standards actually drive different and beneficial design and manufacturing inputs?

Advanced and Robust batteries take the basic platform of a standard SLI battery and may increase the positive grid thickness or add more active material to provide incrementally greater capacity and/or life. EFB batteries start from a unique construction platform that offers functional benefits beyond just a more robust SLI battery.

So EFB batteries are designed and manufactured differently and held to higher performance standards than Advanced or Robust batteries. What does this mean to the end user?

The design features of an EFB allow the battery to provide energy to run electrical load demands of higher content vehicles over and over again without the fear of significant performance decay. Furthermore, unlike standard, advanced or robust SLI batteries, EFB batteries do not have to be at the top of their charge to provide this energy. EFB also provides for an accelerated recharge after a discharge event as seen under real world stop and go driving. This ensures that the battery is taking full advantage of every charging opportunity.

John Miller, Senior Director of Product Engineering, Stryten Energy

Leading the way to renewed and renewable energy.

Copyright 2024 Stryten Energy. All rights reserved.