Optimizing battery safety in military vehicles, or any vehicle, is a primary objective through usage and maintenance. As well, battery safety is a significant factor when selecting batteries for use in military vehicles.

The biggest hurdle facing lithium-ion batteries is safety – an important concern for any battery user — but even more important for military applications. Lithium batteries can be considered volatile if not handled properly. Most of the more publicized lithium battery fires in recent years were due to improper charging, which caused cell overheating.

Preventing Overcharging

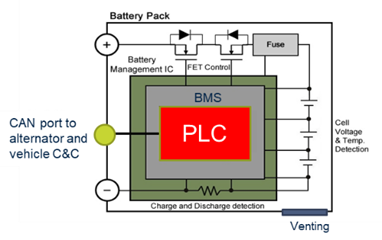

Charge control is addressed by the Battery Management System (BMS). A well-designed BMS will reduce or eliminate the chance of a battery reaching the point of overheating while being charged. A typical lithium-ion battery system will have cells, solid-state switches (FETs), and venting. The BMS will monitor the cell’s temperature, control the FETs, and report to the vehicle via the CAN bus.

Mitigating Smoke and Fire Hazards

Some original equipment manufacturers (OEMs) are developing special containment housings for safety or alternate mounting locations to mitigate potential smoke or fire hazards. In fact, Stryten Energy developed and tested a box that successfully contained a strong lithium reaction (initiated by multiple penetrating bullets) and then vented the resulting smoke and noxious gasses outside the crew compartment while keeping the battery housing temperature at safe levels.

For the military, a big concern is fire due to ballistic damage, which can occur when a bullet or other projectile strikes the battery, causing a short and a potential fire. This type of failure can pose a serious threat to a soldier. Another, more likely concern is smoke from a damaged battery. If smoke infiltrates the crew compartment, it can quickly overwhelm the occupants. Many of the newer lithium battery boxes have venting schemes to prevent smoke from getting into the cab of the vehicle.

Complying with Safety Standards

Stryten Energy has been part of the effort to test and ensure the availability of safe, consistent batteries for military use. In the United States, demonstrating compliance with MIL-PRF 32565 is required before a battery can be listed on the military Qualified Parts List (QPL). It is a challenging document and as of this writing, no vendor has shown full compliance, which means no lithium-based 6T battery has been added to the QPL.

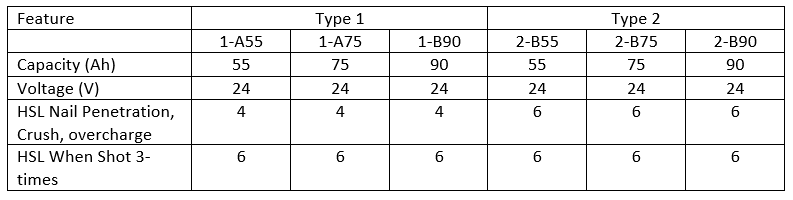

The current MIL-PRF-32565 Revision C defines two types and three capacities of batteries, classified based on Ah capacity and the hazard safety level that occurs when the batteries are abused.

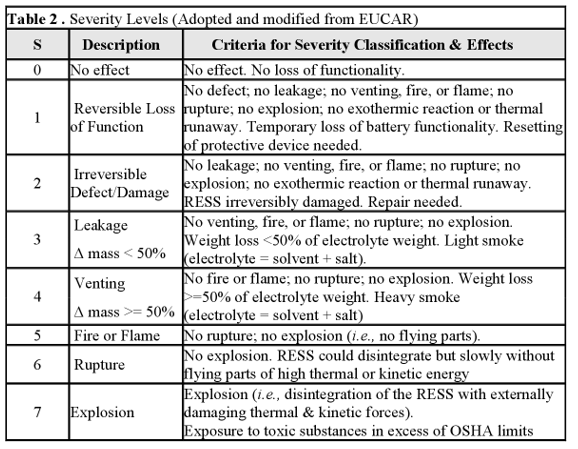

Below are the Hazard Severity Levels (HSL) adopted from the European Council for Automotive R&D (EUCAR):

Many vehicle OEMs may still be wary about using a high-energy lithium battery, and they will consider only Type 1 with HSL level 4. When it comes to battery types, the higher the energy means the higher the potential hazard. But attaining an HSL 4 level is no easy task, so most of the current batch of Type 1 batteries are less than 65Ah.

Battery OEMs have developed even higher energy 6T batteries in hopes of using them for Silent Watch applications. But these batteries tend to be HSL level 7 when penetrated by a bullet and few, if any, military organizations are willing to trade battery capacity at increased risk to soldiers’ lives.

In the final blog in this series, we will look at the integrated battery solutions from Stryten Energy.

Carl Postiglione, Manager, Business Development