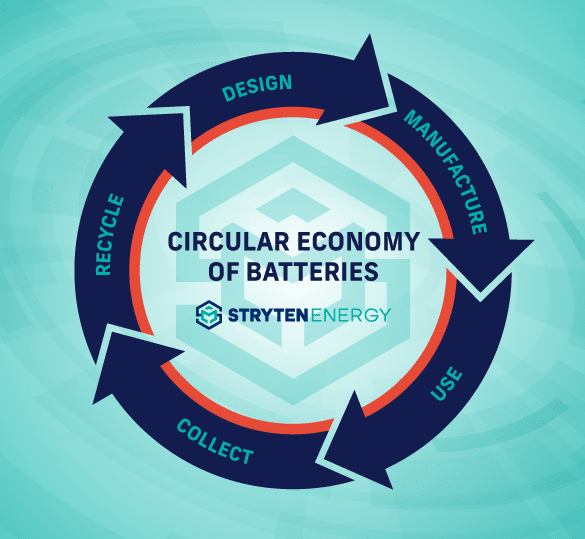

The circular economy of the U.S. lead battery industry is a model for other industries working towards the sustainability of their manufacturing, distribution and recycling processes. The EPA estimates that 99 percent of lead batteries in the U.S. are recycled. With this ample supply of recycled raw materials, a new lead battery produced in the U.S. is typically comprised of more than 80 percent recycled material. At Stryten, each lead battery produced in our U.S. manufacturing plants is made with 90 percent recycled material. And for every battery produced, Stryten recycles the equivalent of that battery through our North American-based recycling partners.

To understand how this process works, let’s start with the important role of each consumer. When you have the battery in your car, boat, tractor or golf cart replaced by a professional, they will ensure the spent lead batteries are properly recycled. But if you decide to replace the battery yourself, there are some important things to remember.

Once a spent lead battery is collected, specialized recycling facilities separate the components for processing. Almost 100 percent of the lead is recyclable, and lead can be continuously reused without losing any future performance capacity. The polypropylene plastic and other casing materials are crushed into small pieces, melted for recycling and molded to make new battery casings. Used battery electrolyte is processed into sodium sulfate, which is used in laundry detergent, glass and textile manufacturing.

When you recycle your used lead battery through a reliable source, you are contributing to the overall sustainability of the lead battery industry. This circular economy minimizes waste, helps protect our environment and ensures abundant supplies of lead and plastic to produce new batteries to keep our supply chains and people on the move.

Leading the way to renewed and renewable energy.

Copyright 2024 Stryten Energy. All rights reserved.